The difference between a roofing company with in-house metal fabrication capabilities and one without is comparable to a professional golfer and a weekend hacker. Rainville-Carlson’s custom fabrication process set us apart from the competition.

Rainville-Carlson’s Metal Manufacturing Methods

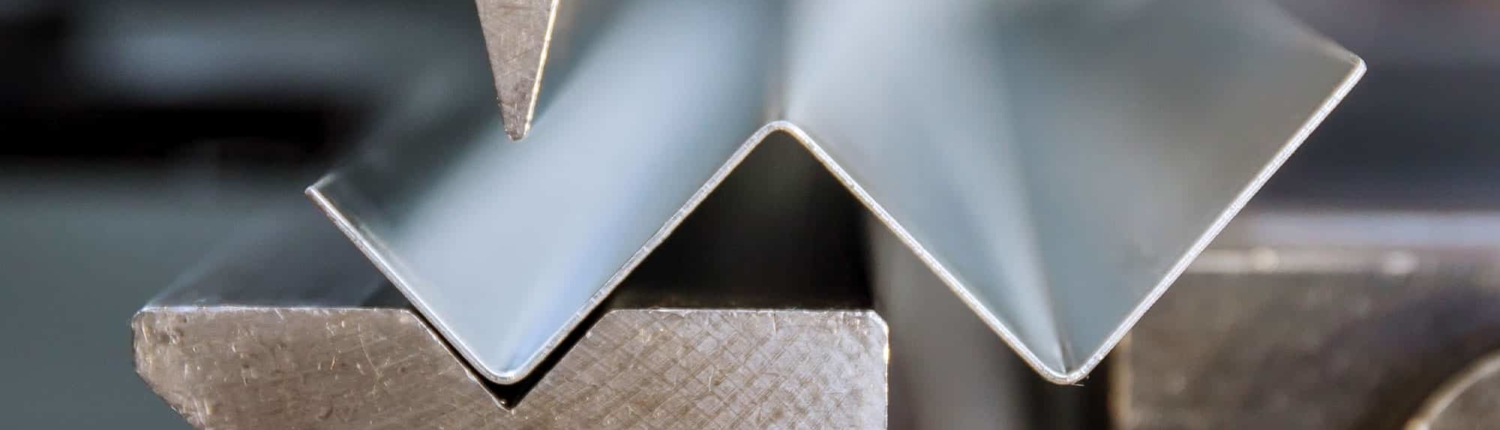

At Rainville-Carlson, our custom metal fabrication process is done entirely in-house at our fabrication shop. Our team of experts uses leading technology, such as water jets and laser cutting, and varied methods during the fabrication process to create high-quality, custom sheet metal roofing that gives your building a look all its own.

Our in-house fabrication process eliminates the need for outside vendors, a perk that greatly benefits you. Without outside vendors, your project gets a streamlined approach. There is never a need to wait for an outside company to create and ship pieces. Without extended lead times, your projects are completed much more quickly and cost you less money.

If a third-party provider makes a mistake or a panel is damaged during shipping, you have to spend extra time waiting on the fabrication process to complete and ship again. Our expertise in the many types of fabrication processes and in-house fabrication shop ensures a quick turnaround time and a finished product with precision cuts.

Our Metal Fabrication Capabilities

We never take a cookie-cutter approach during the fabrication process. To create genuinely custom architectural sheet metal roofing, we use various cutting machines and metal manufacturing methods from start to finish. The different types of fabrication processes allow us to work with a wide range of materials and increase our metal fabrication capabilities.

Rainville-Carlson’s metal fabrication capabilities include all metal types and anything from long cuts to intricate water jetting for desired shapes in artwork and sculptures. We employ several types of fabrication processes, including:

- Welding

- Field welding

- Machining

- Punching

- Shearing

- Metal bending

- Press brake forming

- Laser and plasma cutting

- Hardware insertion

- Powder coating

- Water jet cutting

Water Jet Cutting

While all of our metal manufacturing methods are industry-leading, our in-house fabrication shop’s water jet cutting sets us apart. Our water jet fabrication process delivers unmatched speed and precision. Our machinery allows us to produce flawless pieces up to four times faster than traditional methods. Our quick turnaround time benefits your bottom line by reducing labor costs.

Our fabrication process allows us to use a wide range of metals to meet the look and functionality you want. The precision with which pieces are formed enables us to maximize the raw material used and lower your costs.

If intricate designs are what you need, water jet cuts deliver. Incredible edge quality and flawlessly finished cuts are the standard for Rainville-Carlson’s metal fabrication capabilities. Perfect for both metal structures and custom signage, our water jet cuts deliver custom perfection.

Rainville-Carlson’s metal fabrication capabilities deliver unique, custom roofing and metal structures that help your business stand out. Reach out today to find out how our fabrication process can benefit you.

Benefits of Our Fabrication Process

Our various types of fabrication processes deliver in ways that go beyond traditional metal roofing. Rainville-Carlson can also use them for the preservation and restoration of historical buildings. What better way is there to honor the past than to breathe new life into an architectural masterpiece with a new copper roof, tin plate roof, or steel roof that honors the period in which it was originally built?

Metal roofing is also a way to become more environmentally friendly. Unlike asphalt and rubber roofing materials that absorb heat, metal roofing is reflective. This means your building will have more regulated temperatures, ease your HVAC systems’ workload, and lower utility costs. Even better, our fabrication process creates less waste, and metal roofing is 100% recyclable.

Using our metal fabrication methods, Rainville-Carlson can also create eye-catching accent pieces for your structure. Our customized metal offerings include, but are not limited to:

- Composite wood grain panels

- Window flashing

- Awnings

- Canopies

- Bay windows

- Decorative windows

- Antique panels

Take Advantage of Rainville-Carlson’s Metal Fabrication Capabilities

Rainville-Carlson is here to exceed your expectations. When it comes down to it, you can always rely on our expert metal manufacturing methods to deliver. With over 90 years of experience, Rainville-Carlson uses tried and true types of fabrication processes and cutting-edge technologies for new roofs, maintenance, restorations, or installation and repairs. Reach out today to set up a free consultation.